How to Use Volt-free Dry Contacts for Remote System Monitoring

When monitoring remote devices, it is sometimes easier to use a dry-contact signal from a third-party system rather than a protocol such as Modbus. The connection is relatively easy to make, using a 2-wire cable and allows for a simple ON/OFF signal that can be used to relay a variety of instances such as a change in operating state, fault condition, door opening, smoke or other alarm status. However, it is important to select the right type of contact for the monitoring application.

What are Dry or Volt-free Contacts?

Dry contacts are also referred to sometimes as volt-free contacts or potential free contacts. Dry contacts act as relays or switches and are either in the ON or OFF position. This is referred to as normally OPEN or normally CLOSED. When there is a change of state in the device they are built-into, the contact changes to OPEN or CLOSED, from its original state.

Volt-free or dry contacts do not supply any voltage or current from their own source. They are completely isolated from other electrical circuits, making them ideal to interface with third-party systems with their own monitoring capabilities or a dedicated environmental monitoring device.

This type of contact is commonly used in alarm and fire panels, uninterruptible power systems, access control and HVAC (heating, ventilation and air conditioning) systems. As the contacts are volt-free they are isolated and can be more easily interfaced to by a remote monitoring system without risk of voltage or current damage or electrical interference.

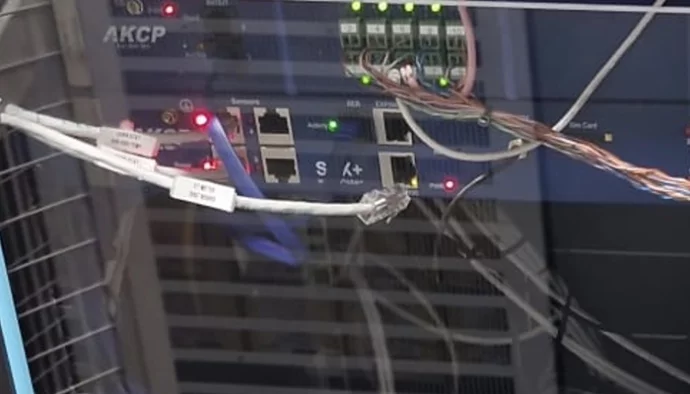

A remote monitoring system could be an environmental monitoring system such as an AKCP sensorProbe+ SPX8 or a building management system.

What are Wet Contacts?

Dry or volt-free contacts differ to ‘wet contacts’. Wet contacts have a ‘wetting’ voltage applied for them to operate. Wet contacts therefore carry their own power (voltage or current) from the source they are built-into, to the connected remote monitoring solution or other third-party devices. Wet contacts are sometimes referred to as ‘hot’ or ‘active’ contacts and can be used to power small indicator lights or motors.

AKCP Monitoring Devices

Dry or volt-free contacts are more versatile for remote monitoring and allow safer and easier integration to monitoring systems within buildings such as server rooms and data centres with environmental monitoring devices installed.

Manufacturers such as AKCP offer a range of dry contact options. A base unit such as the sensorProbe+ can be configured to monitor up to 30 individual dry contacts in a single 1U high rack mounted device. Additional modules can be added via AKCP expansion units, and these can be configured to monitor a range of instances.

AKCP Isolated Contacts (D1i/D2i):

The D1i/D2i isolated contacts are the most commonly used signal, designed for use with volt-free interfaces. The ‘I’ in the SKU denotes isolation with a specification up to 5Vdc maximum.

The D1i/D2i isolated include built-in isolation to protect against electrical noise and ensure safety. They are ideal for monitoring third-party systems where isolation is important i.e. monitoring and connection to sensitive equipment.

AKCP I/O Contacts (D1/D2):

The D1/D2 AKCP contact module allows both monitoring volt-free inputs and the output of dry contact signals to external control devices but without circuit isolation. This type of contact is more suited to simpler configurations where isolation is not required. They can be used for basic digital input (DI) or digital output (DO) functions including acting as actuating relays or reading binary states.

AKCP 20VDC Contacts (D1iV/D2iV):

This DC contacts interface is for monitoring systems that output 5-20Vdc signals. The contacts are isolated to provide protection while handling low-voltage DC signals and are ideal for interfacing with power relays or controls panels that output DC voltage status signals.

AKCP 20VAC Contacts (D1ACV/D2ACV):

This AC contacts interface is for systems that output 5-20Vac signals. The contacts are electrically isolated and are commonly used in AC voltage environments to monitor systems including HVAC and industrial systems.

For both the DC and AC variants, 10 and 20-port versions area available. For reference, a D1 model has 10 signal contact ports and a D2 20 ports.

How Dry Contact Isolation Works

In a dry contact or volt-free contact module, the input (monitored side) is electrically separate to the output (monitoring device side). This isolation prevents direct current flow between the inputs and outputs and so avoids ground loops, voltage spikes and electrical noise interference that could damage connected devise or lead to incorrect signal interpretation.

The most commonly used isolation method is optical isolation (also referred to as opto-isolation or opto-isolated contacts. In this type of configuration, the module includes an optocoupler. This part includes an LED and phototransistor sealed in a light-proof component. The signal and isolation process is as follows:

- Signal Detection: when the dry or volt-free contact closes (or opens), the change in state triggers a small current that lights up the LED on the input side.

- Optical Transmission: the light from the LED activates a phototransistor on the output side, and this then switches the circuit. There is no physical electrical connection between the two sides

- Isolation Barrier: this optical link provides isolation, ensuring high-voltage transients on one side cannot affect the other side of the device

Opto-isolation is the most commonly used due to its inherent reliability and low-cost. Other isolation methods available including magnetic transformers and capacitive coupling.

In AKCP dry contact modules the use of opto-isolating technology improves electrical safety by isolating the inputs from the outputs and making them more suitable for harsh electrical environments where noise could be a common issue. This also leads to less wear and tear and therefore a longer working life for the connected devices.

Wiring the Dry Contact Interface

Dry or volt-free signal contacts require a two-wire signal cable. The mostly commonly used is a twisted-pair (UTP) CAT5/6 cable or a dedicated alarm/ sensor wire (standard 2-conductor 20/2 gauge). Shielding is recommended for long cable runs or electrically noise environments.

AKCP YouTube Video

Selecting the Right Dry Contact Module for an AKCP Base Unit

To select the most suitable contact module:

- Interface Type: does the monitored system have a dry (volt-free) contacts with no output voltage or does it have a voltage signal output? For volt-free interfaces, use the D1i/D2i module for isolated safety or the D1/D2 for basic I/O without isolation.

- Voltage Range: does the monitored system output voltage? If there is an output voltage (i.e. the interface is not volt-free) use the D1iV/D2iV module for DC voltage signals between 5-20Vdc or the D1ACV/D2ACV for AC voltages signals in the same range. Without ensuring compatibility, damage can occur due to mismatched voltages.

- Isolation Requirements: an isolated module is always recommended for environments where there is the potential for electrical noise interference or high voltages locally, especially when monitoring sensitive devices.

When connected, it is important to configure notifications and alerts via the ACKP sensorProbe+ web interface or APS software with specific thresholds for normally open or normally closed states, and test with the connected systems. This testing will provide the configurations and ensure that the right signals and alerts are generated in an alarm condition.

It is important to match the dry contact module to the monitored system output(s) for monitoring reliability and to avoid false alarms and equipment damage.

Summary

Dry or volt-free signal contacts provide an easy way to integrate and automate third-party systems with environmental monitoring systems such as the AKCP sensorProbe+. It is important to match the dry contact module to the monitored system output to ensure reliable monitoring and prevent damage to the connected systems. For more information on AKCP environmental monitoring and dry contact signal modules please contact our Projects Team.