How Creating a Digital Twin Can Improve Data Centre Uptime

A Digital Twin is way to model and replicate the behaviour and processes of a physical data centre. The technology has gained popularity in recent years because it can be used to simulate operational scenarios and predict performance, energy efficiency and reliability.

The Benefits of Digital Twins for Data Centre Operators

Data centre digital twins offer several benefits for data centre operators. They can provide an insight into equipment cooling and power status, usage, and capacity, as well as mapping the IT network and power train. Managers can use the model data to identify suitable areas for improvement, including capacity optimisation and energy savings.

How do you build a Digital Twin?

The first step is to create a virtual model of the physical space. This can be a long and difficult process for a complex environment, such as a large data centre. A simpler, faster, and more accurate solution is to model a containment POD.

A POD is a Performance Optimised Data Centre and most commonly a modular data centre solution, with a single aisle, multiple server rack enclosures and built-in hot and/or cold-aisle containment. Basing the Digital Twin on a containment POD, simplifies the model and helps to create a more accurate Digital Twin.

Some manufacturers such as Panduit may include Digital Twin virtual models of their containment PODs, provided by AKCP. These virtual models have been created in software packages such as AKCP’s AKCPro Server environmental monitoring and control software. This helps to save time and makes it easier to set up an accurate Digital Twin model.

Real-time Monitoring and Analytics

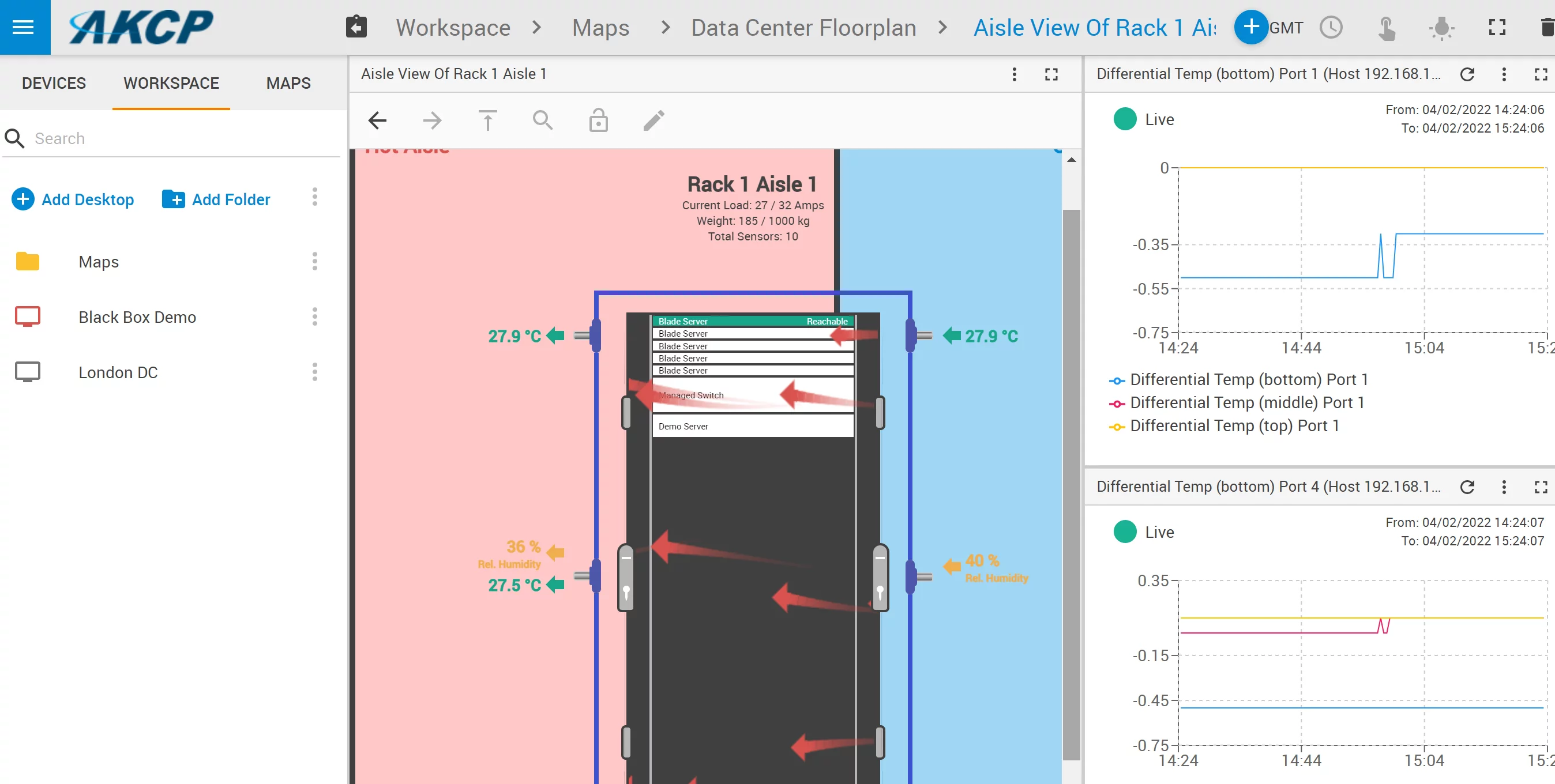

A Digital Twin requires sensors to monitor the physical environment and conditions in real time. For some models, where to place the sensors and how many are required can be complex questions. They can be easily tackled, using thermal map and sensor kits from AKCP, designed specifically for installation in Panduit containment PODs.

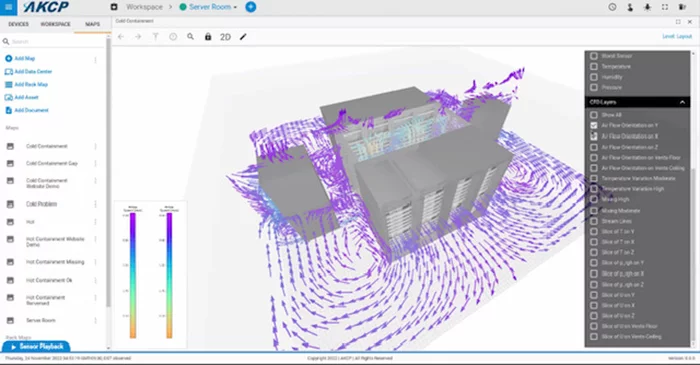

Integration of sensor data into Computational Fluid Dynamics (CFD) can also be easily achieved using AKCP data centre modelling sensors. These can be installed to help produce a graphical representation of the airflow and cooling performance within the POD. Energy consumption, server rack inlet and outlet temperatures, humidity, water leak detection and the physical security of assets are included in the Digital Twin.

The data gathered from this level of monitoring can provide sufficient data for analysis and insights to help data centre operators to detect critical issues and respond appropriately. The data can also be used to identify where energy can be conserved, locate stranded capacity, and improve efficiency.

For more information on Panduit PODs see:https://www.panduit.com/en/products/cabinets-thermal-management-racks-enclosures/thermal-management-containment/aisle-containment.html

Predictive Maintenance

Analysis of sensor data enables the Digital Twin to predict equipment failures and schedule preventative maintenance. This helps to reduce and plan downtime operations and repair costs, as well as helping to extend equipment life.

Virtual Simulations

Failures of critical infrastructure systems (cooling and critical power) can be simulated within a Digital Twin virtual model. From this impact reports can be generated that can be used to improve business continuity plans and implement measures to protect the site from ‘real world’ events and emergencies.

Capacity Planning

Using a Digital Twin helps with capacity modelling. More IT load and capacity can be added, and the model used to determine power requirements, cooling loads and the affects on other critical infrastructure systems.

Digital Twin Challenges

There are challenges when it comes to generating Digital Twins.

Data Reliability

The primary one is data reliability. Digital Twins require accurate data to be useful. Without precise physical models and accurate sensor data, errors occur when performing CFD analysis. This error can be significant, reducing the value of the CFD analysis.

Traditional CFD tools input arbitrary values for the expected rack inlet and outlet temperatures, power utilisation, airflow, air pressures, and cooling systems performance.

For accurate results the input to the CFD model should use real world operational data collected in real time.

System Complexity

Digital Twins have been used in the aviation industry for years. Although a complex system, they can have a very specific performance envelope that can be measured against.

A data centre presents unique challenges with fluctuating demands, server utilisation and capacity load changes. Cooling systems should automatically adjust to match the server loads, as should power usage. Environmental conditions can also change in terms of temperature and humidity.

POD containment systems such as those from Panduit, provide a more controlled environment for data centre operators. Within a large data centre, PODs create a smaller space in which hot and cold air is contained. They present a more well defined and contained environment, that is easier to control, monitor and model.

Within the POD, thermal map sensors can be placed in each server rack where they can be used to checked server rack inlet and outlet temperatures; top, middle, and bottom. ∆T values can be automatically calculated from these values. Power meters on each server rack can measure the heat generated. This sensor data is used to ensure the performance of the POD containment is as designed.

Combining a Panduit POD with AKCPro Server software, environment monitoring base units, and AKCP intelligent sensors creates a more accurate and useful Digital Twin.

The modularity of the system means that as the data centre expands, new containment centres may be added, characterised, and monitored through their own Digital Twin. Rather than a single, large model of the entire data centre, Digital Twins of individual containment pods give a more accurate and useful analysis.

Summary

Creating a Digital Twin of your data centre is an excellent way to manage, monitor and enhance your data centre operations, maintain uptime, and improve efficiency. There are solutions available from AKCP and Panduit that make the deployment of a Digital Twin data centre easier, with end-to-end solutions from containment to sensors to software.