Case Study: UK Atomic Energy Authority (UKAEA) JET Facility Uses AKCP To Monitor Temperature and Humidity

The UK Atomic Energy Authority (UKAEA) uses an AKCP sensorProbe+ environmental monitoring system at their Culham Science Centre HQ in Oxfordshire.

UKAEA are world leaders in developing fusion (the energy source of the stars) for future low carbon electricity, operating the EU’s Joint European Torus (JET) facility for the European fusion community. The UKAEA Electron Kinetics Group studies the action of electrons in the hot gases (or plasmas) of fuel produced at JET.

AKCP wireless environmental monitoring sensors are used to monitor the laboratory temperatures and relative humidity during their experiments.

Why Temperature Monitoring Is Important

Measuring temperature on JET uses a technique known as Thomson Scattering. Detecting the scattered light when a laser beam interacts with an electron determines both the temperature and density of thermonuclear electrons. In JET experiments, the scattered light is detected by avalanche photodiodes (APDs). The detection efficiency of these diodes is very sensitive to temperature. They operate in a controlled environment, requiring temperature sensors to ensure maintenance of required temperature ranges.

Voltage Check Guarantee

Despite the controlled environment, it is not sufficient to guarantee accuracy. The bias voltage of the APDs is adjusted to compensate for temperature fluctuations. The voltage variation is at a rate of 2V/°C. The bias power supplies used are designed to achieve this automatically. As an insurance additional voltage sensors are required to check the system functions as expected.

The AKCP Environmental Monitoring Solution

The ease to use AKCP system allowed the physicists to quickly build the monitoring solution they needed which included sensorProbe+ (SPX+) base units, with temperature sensors, digital voltmeters, Modbus over TCP/IP, and centralised monitoring using AKCPro Server monitoring software.

The 0.1°C resolution of the temperature sensors made them ideal for the measurements. The voltage monitoring required a specialized scientific grade sensor with high resolution. The ADAM 6017 from Advantech was deployed, with a 76uV resolution. Featuring Modbus TCP/IP, its data was brought into the SPX+ and AKCPro Server via virtual sensors.

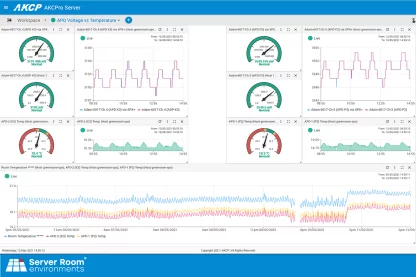

AKCPro Server provided a graphical user interface to display all the collected sensor data. Due to security restrictions, photos within the labs are not permitted. AKCP was allowed to publish screenshots of the AKCPro Server to show the interaction between the AKCP sensors and the laboratory experiments.

System Testing

To check the system functioned as expected, the experiment was conducted with room temperature set to 20°C, 19°C, and 21°C. At each temperature, the system was left for several hours for the photodiodes to reach an equilibrium temperature. The measurements were made by averaging the short-term fluctuations in both temperature and bias voltage. From this, the temperature coefficient of the bias voltage was calculated. The results were within 10% of the expected values.

Additional Measurements

The power of the AKCPro Server virtual sensors was also leveraged to monitor a diverse array of equipment in the laboratory. Programmable relays, mass flow meters, and cryogenic level gauges were all interfaced via Modbus TCP/IP.

Parameters monitored include:

- Mass flow rates of the Helium gas that is boiling off. Spikes on the graph are increased boiloff. (Blue on the graph)

- Liquid helium level within the detector (Red on the graph)

- Liquid Nitrogen shield level. Automatically refills and boils away every 20 hours. (Yellow on the graph)

- Airflow rate through instrument air bearing. (Bottom graph)

Server Room Environments are the AKCP partner for the UK market and continue to support UKAEA and their use of AKCP wireless monitoring sensors.

< Back to Case Studies