Greening UPS and Generator Backup Power Solutions

The way that we are using energy is changing. Hybrid cars are just one example where traditional petrol and diesel engines are combined with lithium-ion batteries to provide a more environmentally friendly form of transportation. Today, new battery and energy storage technologies and advances in on-site power generation allow a server room or data centre to adopt a greener power solution, with lower emissions and one that could be more sustainable in the future.

The idea of combining batteries and carbon fuelled motors is not necessarily a new one. In the world of power protection, uninterruptible power supplies and generators have been installed in combination to provide resilient power protection for several decades.

Uninterruptible Power Supplies and Backup Generators

An online uninterruptible power supply (UPS system) provides protection when the mains power supply is present from a range of pollutants that could disrupt the operation of critical IT systems in a server room or data centre. These include spikes, transients, surges, sags, and brownouts.

When there is a momentary power outage or mains power supply failure, the UPS system runs from its connected battery set. This can be internal to the UPS cabinet or installed in a separate battery cabinet or on a battery stand. The battery set has traditionally consisted of individual valve regulated lead acid (VRLA) maintenance free batteries and is charged by the UPS system or an external charger circuit.

The battery set provides the DC (direct current) input required to power the dc/ac inverter to which the load is always connected in an online UPS system. In a standby or line interactive uninterruptible power supply, the inverter section is powered by the batteries but only activates when there is a sufficiently long or potentially disruptive power outage. For sensitive and critical IT applications, emergency systems, medical and evacuation systems, an online UPS is the preferred technology as the inverter powers the load continuously and the UPS also includes an automatic bypass allowing the UPS to fail safely to mains power if overload or a fault condition occurs.

In a combination power protection system including a UPS and standby power generator, the UPS battery set may only be rated for 10-30minutes runtime. The standby generator provides power to the uninterruptible power supply from a fuel tank which can typically run up to 8-12 hours dependent upon fuel tank size and refuelling services.

See our Guide to UPS Technologies for an explanation of the different types of UPS including offline/standby, line interactive and online.

Sizing Uninterruptible Power Supplies and Generating Sets

Generators provide an alternative source of AC (alternating current) power to the grid and can be used in standby, or primary riles. A primary application runs continuously, and the generator must be rated for this type of application accordingly. A typical example could be when there is no mains power supply available such as an off-grid application or when there are civil construction works on site which mean disruption to the normal mains power supply. In a UPS generator combination, the generator is providing backup power to the uninterruptible power supply. This is a standby or temporary role for the generator.

UPS, Generator and Automatic Transfer Switch (ATS) Installations

A UPS and generator installation consists of three principle components:

- Uninterruptible Power Supply: in a double-conversion or triple conversion UPS, the load is powered directly from the inverter section. This can draw a DC power input from the rectified mains power supply (AC-DC), or the connected battery set (DC). The transfer between DC power sources is instantaneous and break-free due to the internal capacitance of the UPS circuit and there connected critical loads see no break in power. The battery set provides sufficient time for the generator to start-up and cycle to full speed.

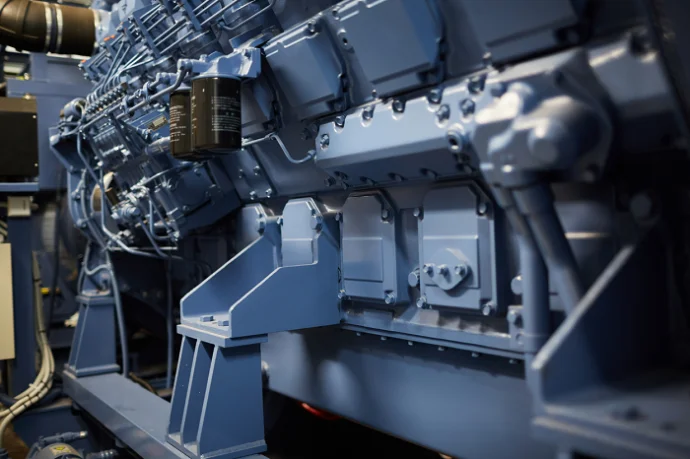

- Backup Power Generator: generators are motors that convert the energy in their fuel supply into electrical energy and provide in the case of a UPS installation, an AC power source and waveform (sinewave) or pseudo mains power supply. An uninterruptible power supply can synchronise to this alternative supply and return its battery set to standby mode and recharge them. The batteries in a UPS and generator backup power solution are only there to cover the generator start-up and synchronisation period which typically takes up to 1minute.

- Automatic Mains Failure (AMF) / Automatic Transfer Switch (ATS): the AMF panel provides an intelligent monitoring and control circuit that automates the transfers to and from generator power. The AMF panel a mains power supply sensing circuit and will only signal the generator to start-up when there is a loss of mains power. The built-in ATS can be set to delay start-up for 10seconds or longer and to avoid unnecessary start-ups for momentary power outages that can be covered by the UPS battery. Once the AMF panel sees a stable power output from the generator, the devices switch into circuit the generator supply. When mains power is restored, the AMF panel monitors waveform and stability of the supply for several minutes before transferring the supply to the UPS from the generator to the mains power supply.

The UPS, generator and AMF panel combination is designed to provide a long duration uninterruptible power source and is commonly used to protect server rooms and data centres which must operate 24/7. Parallel/redundant configurations can be installed to meet the resilience levels required to satisfy the requirements for tier-rating levels from the Uptime Institute.

More information on the Uptime Institute Tier levels: https://uptimeinstitute.com/tiers

UPS and Generator Sizing

A UPS system is sized to protect critical loads that must be kept running 24/7. Some essential loads may also be UPS protected including lighting and air conditioning (where inverter motor driven). In most projects essential and non-essential loads are either dropped when there is a power outage or mains power supply failure or powered from a standby power generator.

- Essential Loads: in and around a server room or data centre are loads that are required during normal operation to ensure continuity of service. These including lighting, air conditioning, evacuation, fire protection and life safety systems. When planning for a power outage a decision must be made as to which of these essential systems must be UPS/generator powered or have their own backup power (emergency lighting) or can be allowed to fail. Server room air conditioning for example should be kept running to avoid overtemperature in the IT environment.

- Non-essential Loads: are not critical or essential to the operation of the business or organisation and can suffer a temporary power failure. Examples include printing services, HVAC controls, heating, and office lighting.

A load table, which classifies the load types and their sizes in kVA/kW will help to identify the total building/application loads and their classification. This data also helps when planning the electrical circuits and in sizing the UPS and generator system.

For most sites sizing an online UPS is straight forward. The total kVA/kW is totalled, a growth factor added (20%) and the resultant figure is used to size a UPS. This approach suits a monoblock UPS but for a modular UPS system, the total frame size and future expansion needs to be considered. For example, a modular UPS may have a frame size for 120kW (4×30kW modules) but only have two installed to provide N+1 redundancy on day-one. In future years two further 30kW modules may be added to provide 90kW (N+1) or 120kW capacity.

The UPS will only power the critical loads and possible some essential. The total kVA/kW required provides a starting point to sizing the generator but a 1:1 (generator to UPS) is never possible due to the operating efficiencies and UPS input power factors.

The normal rule of thumb is to size the generator by at least 1.2 to 1.5 or even twice (2) the size of the UPS dependent upon the UPS rectifier and whether it is a modern IGBT-based system.

To this, the remaining essential and non-essential loads should be added. These will be powered by the generator through a separate circuit from a generator supplied distribution board.

Some UPS manufacturers include specific features in their UPS designs to ensure compatibility with generator supplies. These include ‘walk-in’ which is a gradual transfer of the UPS load from inverter to generator supply. The process is programmable to provide slew-rate control. Walk-in prevents a sudden load being dropped onto the mechanical generator output which could result in voltage and frequency variations. Battery charging can also be disabled in generator supply mode to lower the load the UPS places on the generator. This may be referred to as ‘Diesel Mode’.

High Efficiency UPS Systems

The more energy efficient an uninterruptible power supply is the lower its energy usage and operating costs. A modern UPS system can achieve an energy efficiency of up to 96-97% in full online mode and 99% in line interactive/standby mode. The latter is referred to as ‘Eco mode’.

These high energy efficiency levels are achieved using advanced power electronics design and IGBT-based rectifiers and inverters. Coupled with high input power factors and unity power factor output ratings (kVA=kW) results in a transformerless UPS system that is highly efficient. A its modular form, this type of UPS can also be right-sized to further reduce energy usage without losing resilience and battery charging temporarily disabled for periods in areas where there is a stable mains power supply and infrequent battery usage.

For industrial sites requiring a transformer-based UPS and galvanic isolation, high efficiency transformers are coupled with the advanced power electronics used in a modular system to achieve similar energy savings. Upgrading a 10 year old UPS system can see energy efficiency levels rise 20-25% or more.

Eco Friendly Fuels for Generators

UPS and generator systems must be installed to meet local electrical regulations and building codes. For generators there are two types of pollutant to think about. The first is noise and a generator can be installed with a weatherproof acoustic cabinet to reduce its noise output which must meet local authority requirements.

Diesel remains the fuel of choice for standby power generators for cost and economic reasons and there are directives generator manufacturers must meet such as the Medium Combustion Plant Directive (MCPD) and Specified Generator Controls. Diesel fuel tanks can be built-into the generating set or site close to it. Double-bunded fuel tanks are required to prevent fuel spillage on-site.

Diesel generators may only be allowed to operate for short periods (a few hours a year) compared to generating sets that use more environmentally friendly fuels including Liquid Petroleum Gas (LPG) and biofuels which have significantly lower (Nitrogen Oxide) NOx and Sulphur-Oxide (SOx) emissions.

For more information see: https://datacentremagazine.com/critical-environments/data-centres-and-dirty-fuel

Energy Storage and Lithium-ion Batteries

Energy storage is undergoing a major transition away from lead acid batteries to lithium-ion cells. This can be seen in automatic and solar/wind energy storage systems, and in UPS as well. The benefits of lithium-ion over lead acid are the suitability of the battery technology to rapid recharge/charge cycling, footprint and design life which can be 10-15 years compared to 5-10 for lead acid batteries.

Some UPS systems can now be installed with a lithium-ion battery. This opens the potential form the UPS to be connected to a larger Li-ion battery pack for energy storage which can charge from the local mains power supply or a renewable energy source and so remove the need for a diesel generator on site.

The investment required for this eco-friendlier solution is potentially 2-3 times that for a UPS and diesel generator combination, but costs will come down in the next 5-10 years as lithium-ion battery manufacturing ramps up. There are also developments in energy storage battery technology that could replace lithium with lower cost, longer design life and higher capacities.

Summary

For server rooms and data centres looking for more than 10-30 minutes of backup power, the choice falls between either installing a larger battery pack or a standby power generator. A limiting factor for many sites will be the amount of floor space required for the battery pack if this is the preferred solution. Even if the site has a dedicated UPS and battery room, the floor space required may not be sufficient for a 100kVA UPS and 2hour battery pack.

Generating sets are the accepted alternative but require a dedicated area outside the building, concrete plinth and fuel storage and refuelling. An automatic mains failure (AMF) panel must also be installed to monitor and control the transfer to and from generator power. Whilst diesel remains the preferred fuel there are more environmentally friendly alternatives.

Eventually energy storage based on lithium-ion or a newer technology including solid state batteries may provide a suitable alternative to generating sets. Within the 10-250kW load range may be possible in the next 5-10 years and eventually for larger kW and MW loads as grid-scale energy storage systems become more widely used and drive down manufacturing and material costs. m