Batteries for Datacentre UPS and Energy Storage Systems

Ever since the UK Government introduce the feed-in-tariff (FIT) for solar PV and wind turbine installations, one of the biggest challenges has been how to store the generated energy for later use. Lead acid batteries have limited capabilities when it comes to frequent energy storage and discharge cycles and are more suited to standby power applications. Applications including electric vehicles and mobile computing applications also required an energy storage mechanism that could cope with rapid charge/recharge cycles and offer a longer working life. Lithium-ion batteries have rapidly become the energy storage device for these applications and are slowly being adopted into UPS system applications.

Uninterruptible Power Supplies and DC Power Sources

An uninterruptible power supply requires a source of DC (direct current) from which to power the inverter section. A UPS inverter ‘inverts’ DC power into AC (alternating power) which is supplied to the connected load. When mains power is present the DC supply is provided by a rectifier/converter in an on-line UPS which converts the AC waveform of the mains power supply into two levels of DC power. One to supply the inverter and the other to charge the battery set. When the mains power supply fails, the battery set DC power supplies the inverter input. The process gives rise to the term ‘double conversion’ or ‘AC-DC-AC’ uninterruptible power supplies and in an online UPS system the transfer from and to battery is ‘no-break’ due to internal capacitance within the electronic circuitry.

Lead Acid UPS Batteries

The traditional UPS battery for a server room or datacentre uninterruptible power supply has been the ‘lead acid’ type. The battery industry traditionally used glass-cased ‘wet’ batteries with a liquid hydrochloric acid electrolyte. The battery electrolyte level was visible through the glass case and could be topped up if required.

One of the biggest innovations in lead-acid battery technologies occurred with the introduction of valve regulated lead acid (VRLA) batteries using a GEL electrolyte and plastic cases. The technology was rapidly adopted for standby power applications including uninterruptible power supplies, emergency lighting systems, security alarm panels and motors including generator starting circuits.

For UPS systems, the VRLA battery offer a low-cost source of DC power with a relatively low-tech battery charging circuitry need. VRLA UPS batteries are maintenance free and up to 90% of their components can be recycled including the plastic cases, lead plates and electrolyte gel.

Lead acid UPS batteries are typically of the 5-year or 10-year design life. The actual working life is dependent several factors including the number of charge and discharge cycles the batteries are subjected to and the ambient temperature they are exposed to. Most UPS chargers offer temperature compensated charging and will use a combination of trickle and float charging. UPS lead acid batteries can typically be recharged to 80% within 24 hours but then require a slower charging rate to reach 100% charge over several more hours.

Heat kills VRLA lead acid batteries. The ideal ambient temperature for a lead acid battery is 20-25˚C. For each one degree rise above 30˚C the design life halves. Lead acid batteries are also exothermic and during charging add to the local ambient temperature as the battery cells generate heat as a product of the chemical reaction that occurs during charging. During discharge, lead acid batteries are endothermic and absorb heat.

Most lead acid batteries will last from 3-4 and 7-8 years respective to their design life (5-year and 10-year). Longer life lead acid batteries area available up to 15 to 20 years but are far more expensive as their design uses more materials and the pricing does not benefit from the same level of mass manufactured scale economics associated with 5-year and 10-year design life batteries.

The ‘heat’ issue gives rise to a visible sign that VRLA lead acid UPS batteries are reaching their end-of-life. The plastic case buckles and this can lead to a white deposit of air-exposed GEL electrolyte around the metal connection terminals.

In addition to ambient temperature, lead acid batteries are also designed for a range of complete charge/discharge cycles. Typically this can be 300-400. Most lead acid batteries are only called upon to provide partial discharges. This is because momentary power outages are more common than complete power failures and in a critical power installation such as a datacentre or server room, hospital or industrial application, the runtime is often backed-up by a local standby power generator.

Of the thousands of UPS systems installed in IT, server room, datacentre and industrial applications, well over 90% will use lead acid batteries. The battery technology is suitable for storing electrical energy for several minutes up to several hours. There are alternative DC power sources available.

Alternative DC Power Sources

The two principle DC energy storage systems that can be used with modified uninterruptible power supplies include Super Capacitors and flywheels.

A capacitor stores electrical energy and are used within electronic circuits and the electrical circuits within uninterruptible power supplies. Internal capacitance is used to maintain the output circuit of a UPS inverter during the transfer between mains power and battery supplies. In a Super Caps UPS system, high energy storage ‘super’ capacitors are used in place of the traditional battery set. The capacitors can rapidly store electrical energy and can be subjected to thousands of charge/discharge cycles. Two limitations are the amount of energy that can be stored which is measure in milliseconds rather than minutes and the fact that capacitors can dry-out and if not replaced can present a thermal-runaway related fire risk. Super Cap UPS are suited to specific applications including transportation (including rail) and industrial manufacturing processes requiring protection from momentary power outages.

DC flywheels can provide longer runtime periods than super capacitors, but this may also be measured in time units from milliseconds to one or two minutes at full load. The flywheel consists of a large mass spinning within a vacuum. When a mains power supply is present, the mass is spun up to several thousand revolutions per minute. When the mains power supply fails, the kinetic energy of the mass is ‘collected’ and converted into a DC power source which can support a UPS inverter. As the energy generation potential is longer (up to two minutes or more), the DC UPS energy can be used to either reduce the initial impact on a UPS battery set or to start-up a local standby power generator. Reducing the initial impact on the local lead acid UPS battery can help to extend its working life; reduces the number of partial charges and overall ‘wear and tear’.

Lithium-ion Batteries for Datacentre UPS Systems

Lithium-ion batteries have become the preferred choice of lead acid for energy storage applications. There are now several competing energy storage devices using li-ion batteries at the grid, commercial and domestic levels. The battery technology is suitable for use with solar PV and wind turbine installations to store power for later usage during the night or when there is too little or now wind. Lithium-ion batteries can also be used to store power during ‘off-peak’ pricing periods for later usage when electricity prices are higher.

Lithium-ion batteries are more temperature tolerant than lead acid batteries and can work above 30˚C and higher, making them more suitable for use within the higher temperature envelopes recommended by ASHRAE for datacentres in order to improve their energy efficiency. A li-ion battery can also have a working life of 10-15 years or more and is typically capable of several thousand charge/discharge cycles.

Some UPS systems are now available with a lithium-ion battery option. These UPS are adapted or manufactured specifically for this purpose. The reason is that the require a more sophisticated battery management system to ‘cruder’ type used for lead acid batteries. It is important when using lithium-ion batteries to ensure a balance charging mechanism and monitor the potential for ‘hot-spots’ which can lead to thermal runaway.

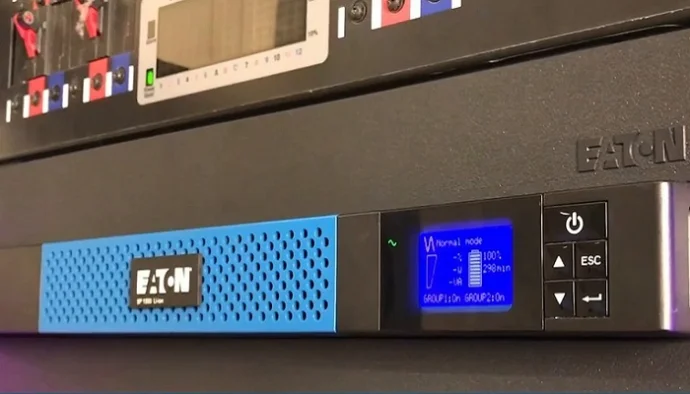

Manufacturers including as Schneider/APC and Eaton now offer small single-phase UPS systems with a lithium-ion UPS battery within a single rack mount arrangement. These are ideal for use within a datacentre rack cabinet. Larger three-phase UPS systems with lithium batteries are also available. This type of system is suitable for storing locally generated renewable power and allowing the datacentre to take advantage of grid balancing demanding side response (DSR) programs for which the datacentre can receive a feed-in-tariff to offset the initial Capex and OpeX costs.

For more information on the types of lithium battery available visit: https://en.wikipedia.org/wiki/Lithium-ion_battery

Summary

The initial role of a battery set within a UPS system has not changed for IT, server room and datacentre applications. The battery provides a source of DC power to allow the UPS inverter section to continuously power the load. Alternative DC power sources are available including super capacitors and flywheels, but their use is limited due to the lower amounts of energy they can provide. Lithium-ion batteries provide a more suitable alternative for datacentre UPS system applications and will become more widely adopted as their costs fall lower through increased usage within both the power and electric vehicle industries. Lithium-ion batteries do require a more sophisticated battery management system than lead acid batteries and are more difficult to recycle, requiring more specialist recycling centres and procedures.